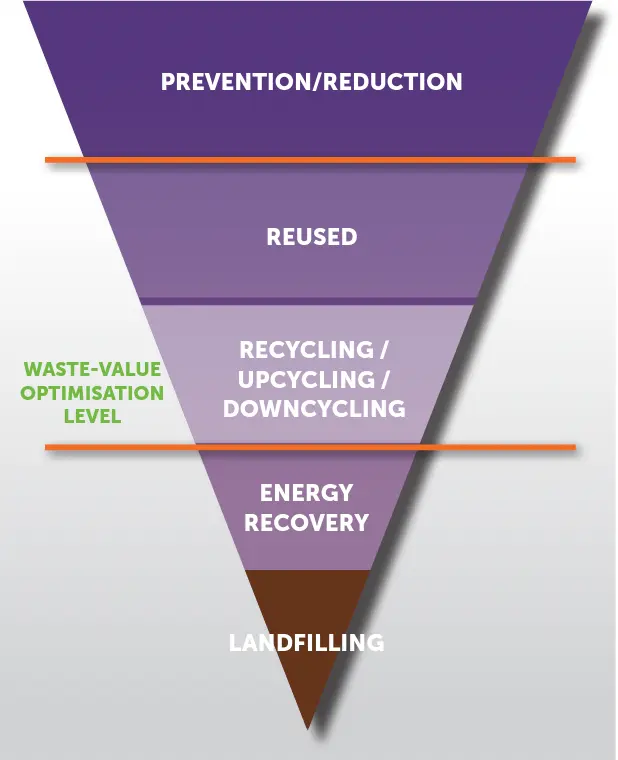

We will accelerate innovation in textile recycling, utilizing fibre 20% recycled composition in our viscose production. Through collaboration with supply chain partners and innovators, we aim to scale new circular approaches, and advance the collection, sorting and recycling of textile waste.

We believe in utilising our scale for good and our commitment to circularity is no different. Instead of developing specific fibre types that offer customers a circular and recycled option but at smaller quantities and higher prices, we have focused our attention on increasing the amount recycled materials in our entire viscose production. It is our aim that this will transform the entire industry.