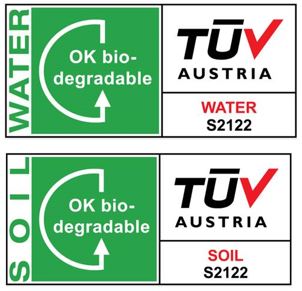

Jakarta, 25 January 2021 – Asia Pacific Rayon (APR) has announced that tests have confirmed the biodegradability of its fibers in fresh water and soil. The tests were carried out by independent research laboratory Organic Waste Systems and, as a result, APR’s viscose staple fibers (VSF) have been awarded the international OK biodegradability WATER and OK biodegradability SOIL labels by accredited certification board, TUV Austria.

Biodegradability in soil offers positive benefits for viscose and the environment, as the VSF fibers can break down naturally in soil after being used. The OK biodegradable SOIL label guarantees that a product will completely biodegrade in the soil without adversely affecting the environment.

Additionally, products certified with the OK biodegradable WATER guarantee can decompose in a natural freshwater environment and substantially reduce waste in water environments.

According to the OK biodegradable SOIL and OK biodegradable WATER certification criteria, three requirements have to be met to conform to the schemes:

- Material characteristics conform to EN 13432 (2000),

- Aerobic biodegradation at ambient temperature in soil and aqueous aerobic biodegradation,

- No adverse ecotoxicological effects in OK Biodegradable SOIL and the product does not contain any components on the list of Substances of Very High Concern (Annex XIV or the REACH) for OK Biodegradable WATER.

APR VSF fibers fulfil these requirements and lab results demonstrate that, within 28 days, fibers reached a biodegradation level of 93.6% +/- 4% in soil and complete biodegradation in the aqueous aerobic diodegradation test.

“APR’s VSF is 100% bio-based and uses renewable dissolving wood pulp harvested from responsibly managed forest plantations to produce biodegradable fibers. These fibers can be returned to nature after use. We’re seeing more demand from consumers for natural fibres that are better for the environment, unlike synthetic alternatives,” said Cherie Tan, Vice President, Sustainability & Communications, Asia Pacific Rayon.

“Consumers want sustainable fashion more than ever, and choosing a natural fibre is certainly a step in the right direction. APR operates a circular business model integrating our operations from renewable plantations to the production of biodegradable fiber. We are committed to partnering with our customers and the entire textile value chain to make circular fashion become mainstream for the sector,” she said.

APR’s commitment to innovation and circularity is supported by the continued investment by its parent company. RGE Group, to accelerate next-generation textile fibre innovation and technology. This will turn further pave the way for closed-loop production systems.

About Asia Pacific Rayon

Asia Pacific Rayon (APR) is the first fully integrated viscose rayon producer in Asia. The factory with 240,000 tonne capacity, located in Pangkalan Kerinci, Riau, uses the latest production technology to produce high-quality rayon to meet textile needs. APR is committed to becoming a leading viscose rayon producer that upholds the principles of sustainability, transparency and operational efficiency, serves the interests of the community and the country, and provides value to customers.

www.aprayon.com

Media contact:

Djarot Handoko

Head of Corporate Communications, Asia Pacific Rayon

Djarot_Handoko@aprayon.com